- Shopping, made easy.

- /

- Get the app!

The 410 stainless steel thread cutting screw has a plain finish, a Type 25 point style, and a pan head with a Phillips drive. The screw, also called a type BT thread cutting screw, has coarse threads and is suitable for use with plastics and other soft materials. The type 25 point tapers down to a blunt edge and directs chips out of the hole to prevent clogging. The large cutting surface enables screw installation with minimal rotating force. The 410 stainless steel material offers high strength and hardness, and resists corrosion in mild environments. The material is magnetic. The pan head has a flat top and short vertical sides with a rounded top edge. The Phillips drive has an x-shaped slot that accepts a Phillips driver and is designed to allow the driver to slip out of the head to help prevent over-tightening and damage to the thread or fastener.

Thread cutting and thread rolling screws, two types of self-tapping screws, are threaded fasteners that create a mating thread in the wall of a hole. The two screws differ from each other in the way that they create the threads. Thread cutting screws cut the wall of the hole to create the thread, creating material chips that need to be cleared away from the hole to prevent clogging. Thread rolling screws, also called thread forming screws, do not remove material but instead press against the wall of the hole to displace the material and form the threads.

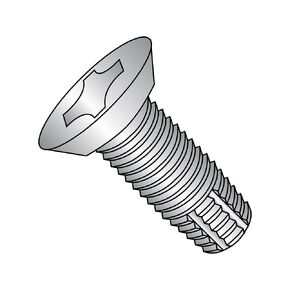

Small Parts 1408FPU188 18-8 Stainless Steel Thread Cutting Screw, Plain Finish, 82 Degree Flat Undercut Head, Phillips Drive, Type F, 1/4"-20 Thread Size, 1/2" Length (Pack of 25)

KWD 3

Small Parts 1408FPU188 18-8 Stainless Steel Thread Cutting Screw, Plain Finish, 82 Degree Flat Undercut Head, Phillips Drive, Type F, 1/4"-20 Thread Size, 1/2" Length (Pack of 25)

KWD 3

Small Parts 0208LPP Steel Thread Rolling Screw for Plastic, Zinc Plated, Pan Head, Phillips Drive, #2-28 Thread Size, 1/2" Length (Pack of 100)

KWD 3

Small Parts 0208LPP Steel Thread Rolling Screw for Plastic, Zinc Plated, Pan Head, Phillips Drive, #2-28 Thread Size, 1/2" Length (Pack of 100)

KWD 3

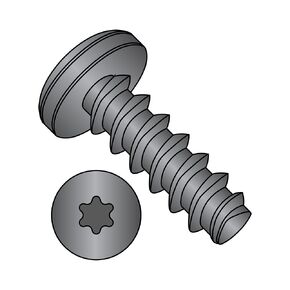

Small Parts 0606LTPB Steel Thread Rolling Screw for Plastic, Black Oxide Finish, Pan Head, Star Drive, #6-19 Thread Size, 3/8" Length (Pack of 100)

KWD 3

Small Parts 0606LTPB Steel Thread Rolling Screw for Plastic, Black Oxide Finish, Pan Head, Star Drive, #6-19 Thread Size, 3/8" Length (Pack of 100)

KWD 3

Small Parts 0812APP188B 18-8 Stainless Steel Sheet Metal Screw, Black Oxide Finish, Pan Head, Phillips Drive, Type A, #8-15 Thread Size, 3/4" Length (Pack of 50)

KWD 10.500

Small Parts 0812APP188B 18-8 Stainless Steel Sheet Metal Screw, Black Oxide Finish, Pan Head, Phillips Drive, Type A, #8-15 Thread Size, 3/4" Length (Pack of 50)

KWD 10.500