- Shopping, made easy.

- /

- Get the app!

Specification:

Volume:25ml/50ml/100ml/150ml/200 ml/250ml/300ml/500ml, other customized according to user needs

Seal Structure: sealed by PTFE chamber

Shell Material: stainless steel 304

Chamber Material: high quality PTFE

Heating/ Cooling rate: 5c/min

Max temperature: 220℃

Max pressure: 3Mpa

Feature:

1.Insulation, high lubrication.

2.No adhesion, no poison;Anti-pollution, anti-leakage.

3.Good corrosion resistance, no harmful substances spill.

4.Pollution reducing, use safety.

4.With polytetrafluoroethylene bushing, acid and alkali resistant.

How to use it :

- Pour the reactant into the reactor kettle, and to ensure feeding coefficient is less than 0.8.

- You should put the corrosive reaction into PTFE bush, and should be assured kettle body from corrosion.

- Hydrothermal synthesis reactor will be placed on the heater, in accordance with the provisions of the heating rate of heating to the desired reaction temperature (less than the required safety temperature).

- When finishing heating and need to cool, it's also in strict accordance with the provisions of the cooling rate operation, to facilitate the safety and reactor life.

- After confirmation of intra-abdominal temperature below the boiling point solvents reaction system, it could be allowed to be open tank lid and do a follow-up operation.

- Hydrothermal synthesis reactor each time after use to clean, to avoid corrosion. Kettle body, kettle lid seal line to pay particular attention to clean and prevent damage to the bumps.

Heating Mantle Fisatom with Controller, 500ml, Reinforced Thermal Isolation

KWD 41

Heating Mantle Fisatom with Controller, 500ml, Reinforced Thermal Isolation

KWD 41

DC 12V/24V Mini Vacuum Pump, 10W 15L/min Electric Portable Air Pump with Holder, Negative Pressure Suction Pumping Air Compressor Diaphragm Pump for DIY Projects & Gas Analysis Sampling(24V)

KWD 10

DC 12V/24V Mini Vacuum Pump, 10W 15L/min Electric Portable Air Pump with Holder, Negative Pressure Suction Pumping Air Compressor Diaphragm Pump for DIY Projects & Gas Analysis Sampling(24V)

KWD 10

RSP-320-5 CCG Mean Well Enclosed Type Single Output Switching Power Supply MeanWell RSP-320-5

KWD 23

RSP-320-5 CCG Mean Well Enclosed Type Single Output Switching Power Supply MeanWell RSP-320-5

KWD 23

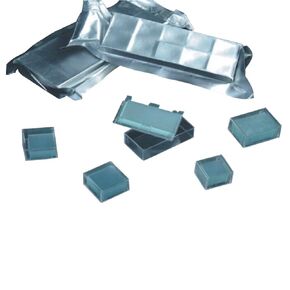

Square Cover Glass, 10x10mm Microscope Slide Covers, Cover Slips,0.13mm Thickness, Pack of 1000pcs (10 Boxes)

KWD 5.500

Square Cover Glass, 10x10mm Microscope Slide Covers, Cover Slips,0.13mm Thickness, Pack of 1000pcs (10 Boxes)

KWD 5.500