- Shopping, made easy.

- /

- Get the app!

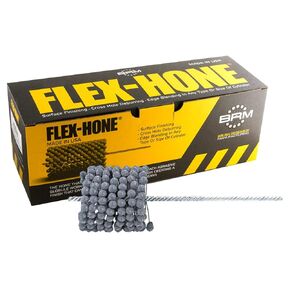

The Brush Research FLEX-HONE® for Rotors imparts the ideal surface finish on new and turned rotors to insure instant brake pad seating and eliminate noise. This unique tool utilizes BRM's proprietary Flex-Hone technology to create a non-directional or basket weave finish while removing torn and folded material produced by turning or truing. Friction induced brake noise is the number one reason for customer dissatisfaction and returns when purchasing new brakes. By removing the jagged peaks from the turned brake surface, the tool produces a plateau finish with much higher bearing area which translates to quieter brakes. The Flex-Hone for Rotors can also be used on flywheels for improved friction performance. The finish produced by the Flex-Hone for Rotors is far more consistent and repeatable compared to sandpaper or discs.

-12%

Brush Research 00054 Chamber Flex-Hone, Aluminum Oxide, 12 Gauge, 800 Grit (Pack of 1)

KWD 14.500

-12%

Brush Research 00054 Chamber Flex-Hone, Aluminum Oxide, 12 Gauge, 800 Grit (Pack of 1)

KWD 14.500

Brush Research GB418320AO FLEX-HONE®, 4-1/8" (105mm) Diameter, 320 Grit, Aluminum Oxide Abrasive (Pack of 1)

KWD 38.500

Brush Research GB418320AO FLEX-HONE®, 4-1/8" (105mm) Diameter, 320 Grit, Aluminum Oxide Abrasive (Pack of 1)

KWD 38.500

Brush Research 06459 Chamber Flex-Hone, Silicon Carbide, 12 Gauge, 400 Grit (Pack of 1)

KWD 17

Brush Research 06459 Chamber Flex-Hone, Silicon Carbide, 12 Gauge, 400 Grit (Pack of 1)

KWD 17

-16%

Brush Research GB334320AO FLEX-HONE®, 3-3/4" (95mm) Diameter, 320 Grit, Aluminum Oxide Abrasive (Pack of 1)

KWD 36.500

-16%

Brush Research GB334320AO FLEX-HONE®, 3-3/4" (95mm) Diameter, 320 Grit, Aluminum Oxide Abrasive (Pack of 1)

KWD 36.500