- Shopping, made easy.

- /

- Get the app!

Product manufacturing steps:

1. Prepare the heat transfer printing drawings that have been printed with heat transfer ink in advance;

2. Keep the heat transfer surface clean and tidy;

3. Fix the heat transfer paper and MDF board with high-temperature adhesive tape;

4. Debug the heat transfer machine: 200 degrees Celsius, 60 seconds, medium pressure.

5. Place the MDF board on top of the paper and place it in the heat transfer area. Wait for the temperature to rise and pull down the handle.

6. Take out the printed MDF board and tear off the heat transfer paper to obtain the finished product.

The installation method of clock accessories is as follows:

First, align the side of the clock body block with a white protrusion with the small hole in the middle of the back of the glass painting, then thread it through.

Then, insert the golden circular washer and nut into the white plastic rod that has just passed through from the direction of the glass printing surface.

Use a small wrench to tighten the golden nut to the glass surface, then install the hour hand, then the minute hand, and finally install the second hand and press it tightly!

Due to the lack of a protective glass cover on the outside of the glass painting, unlike the finished watches sold in shopping malls that have transparent covers for protection, the hands of all watches are easily knocked off. Please reinstall them yourself!

Notes:

Manual measurement, please allow slight errors on size.

The color may exist a slight difference due to different screen displays.

Trademark Innovations Small Wood and Leather Decorative Chest

KWD 8.500

Trademark Innovations Small Wood and Leather Decorative Chest

KWD 8.500

-14%

ECOOPTS 11 inch Artificial Topiary Ball Lifelike Plants Boxwood Decoration for Home Garden Porch Backyard Balcony Wedding Party (1 Pack)

KWD 12

-14%

ECOOPTS 11 inch Artificial Topiary Ball Lifelike Plants Boxwood Decoration for Home Garden Porch Backyard Balcony Wedding Party (1 Pack)

KWD 12

-10%

ONEUS 6th Mini Album - Blood Moon (Set ver.) 3Album

KWD 22

-10%

ONEUS 6th Mini Album - Blood Moon (Set ver.) 3Album

KWD 22

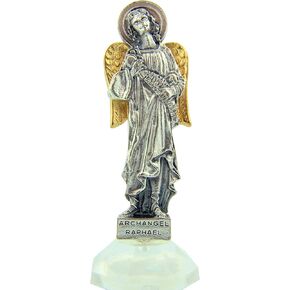

Lumen Mundi Travel Protection Patron St Christopher The Christ Bearer Adhesive Car Auto Statue Figure

KWD 6

Lumen Mundi Travel Protection Patron St Christopher The Christ Bearer Adhesive Car Auto Statue Figure

KWD 6