- Shopping, made easy.

- /

- Get the app!

The main body uses rubber with fiberglass inside and imported canvas on the teeth for strength and durability.

Belt Cleaning:

1. Clean the belt and pulley should be a rag with a little non-volatile liquid wipe test, do not diffuse soak in detergent or use cleaning wash belt, do not use sandpaper to wipe or use pointed said object to scrape the belt.

2. The belt must be kept dry before installation and use.

Belt inspection:

1. Check the belt for cracks or wear.

2. Check whether each pulley is on the same plane.

3. Check the rest of the drive components, such as the symmetry, durability and lubrication of the bearings and bushings.

Belt test run:

1. It is recommended to adopt the test run procedure, during which the running condition should be closely monitored, to see if there is any abnormal vibration, to listen carefully if there is any abnormal noise, and to check the heating condition of the bearings and the motor.

2. For timing belts, there is very little slack during operation, so generally there is no need to readjust the tension, but it is still recommended to start the device and observe the performance.

BCZAMD Toaiot 3D Printer Accessories Resin Cleaning Tool Dry Wipes - Lint Free - Flushable Towel - 100 Counts 15x20cm/ 5.9*7.8in for Cleansing Silicone Mat Model Vat Tank Air Purifier Part Imdinnogo

KWD 5

BCZAMD Toaiot 3D Printer Accessories Resin Cleaning Tool Dry Wipes - Lint Free - Flushable Towel - 100 Counts 15x20cm/ 5.9*7.8in for Cleansing Silicone Mat Model Vat Tank Air Purifier Part Imdinnogo

KWD 5

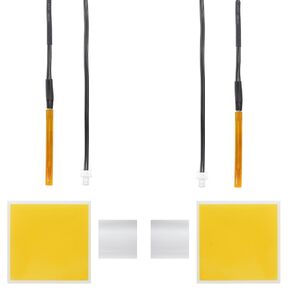

3D Printer Accessories Prusa MK4 MK3.9 HeatBed Thermistor Set Replacement Kit - 2Pcs: Not Compatible with MK3S MK3 MK2.5S MK2.5 MK2S Mini MK3S+ MK2 BCZAMD

KWD 10

3D Printer Accessories Prusa MK4 MK3.9 HeatBed Thermistor Set Replacement Kit - 2Pcs: Not Compatible with MK3S MK3 MK2.5S MK2.5 MK2S Mini MK3S+ MK2 BCZAMD

KWD 10

3D Printer Accessories Bambulab X1 X1C Ceramic Heater and Thermistor 24V 48W Upgrade Kit 300℃ High Temperature Sensor with Thermal Grease Retaining Clip

KWD 4

3D Printer Accessories Bambulab X1 X1C Ceramic Heater and Thermistor 24V 48W Upgrade Kit 300℃ High Temperature Sensor with Thermal Grease Retaining Clip

KWD 4

-18%

3D Printer Accessories Must-Have Tool for Extuder Unclogger: 4Pcs 1.5x150mm Unclogger 2Pcs Sleeve for FDM 3D Printer Prusa MK3 MK4 BambuLab X1 X1C P1P P1S Ender3 Ender 5 AD5M Pro Neptune4

KWD 7

-18%

3D Printer Accessories Must-Have Tool for Extuder Unclogger: 4Pcs 1.5x150mm Unclogger 2Pcs Sleeve for FDM 3D Printer Prusa MK3 MK4 BambuLab X1 X1C P1P P1S Ender3 Ender 5 AD5M Pro Neptune4

KWD 7