- Shopping, made easy.

- /

- Get the app!

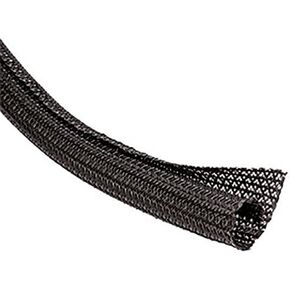

By adjusting the physical characteristics of the polyethylene terephthalate filaments, the Engineers at Techflex have produced a product with the same specifications as our pet sleeve with the unique advantage of being able to cut the material with ordinary scissors and still maintain an extraordinarily fray-resistant end without the addition of chemical binders or adhesives. Flexo clean cut is ideal for field installers and other situations where access to a hot knife is impossible. Clean cut's fray resistant properties allows frequent expansion of the cut end without unraveling. When cut with a hot knife, clean cut produces a clean, smooth and virtually fray less end. Clean cut is braided for maximum coverage while still allowing enough expansion for easy installation over plugs and connectors.

Techflex PTN0.25BK25 Flexo PET Braided Sleeve, 1/4" x 25' L, Black

KWD 3.500

Techflex PTN0.25BK25 Flexo PET Braided Sleeve, 1/4" x 25' L, Black

KWD 3.500

-23%

Techflex F6N0.25BK Flexo F6 General Purpose 1/4" Braided Cable Sleeve, 100', Black

KWD 18.500

-23%

Techflex F6N0.25BK Flexo F6 General Purpose 1/4" Braided Cable Sleeve, 100', Black

KWD 18.500

Techflex 1/4" Split F6 Braided Cable Sleeving Wrap, Split Loom, (25FT)

KWD 5

Techflex 1/4" Split F6 Braided Cable Sleeving Wrap, Split Loom, (25FT)

KWD 5

Techflex 1/8 Inch Flexo Clean Cut Braided Cable Sleeve - Black - 10 Feet

KWD 3.500

Techflex 1/8 Inch Flexo Clean Cut Braided Cable Sleeve - Black - 10 Feet

KWD 3.500