- Shopping, made easy.

- /

- Get the app!

Patches with glue will work just fine, but considering that carrying glue around can be inconvenient, glue can easily leak from squeezing, which can cause your bag to stick. After you patch a tube, the glue starts to dry in the tube. When you're patching punctures on the road, you'd better have patches that don't require glue, so we've developed this glue-free patch.

Puncture repair is a very important thing in the riding process, especially when you have a puncture after more than ten kilometers away from home, it will bring you a lot of trouble. This requires you or a friend with you to carry a puncture repair tool. A tire repair tool is a consumable item, and our patch is a great addition.

Instructions:

1. Completely deflate the inner tube after finding the puncture point

2. Grind the edge of the hole into a new surface with a metal file first. The polished area is slightly larger than the size of the tire patch. At this time, the puncture point should be in the center of the polished area, and then ensure that the polished inner tube is free of foreign matter and water. Stains and oil stains.

3. Put the patch on the fitting surface of the inner tube properly, and press it for 10 seconds. Please avoid air bubbles or wrinkles during the operation.

About the possible reasons for some failed cases:

1. The surface of the inner tube has not been properly filed, and the patch cannot be bonded to the old surface,there may be a gap between the adhesive surfaces without the necessary pressing of the patch.

2. The hole center of the inner tube deviates from the center of the patch, which makes the force of the patch on the air pressure generated by the hole uneven, so that the patch opens a gap for the airflow.

3. The new surface after grinding has stains, water stains, grease (especially oil stains, which can ruin a patch) and foreign objects.

Oumers 3 Pack of Bike Spoke Wrench Kit, Forged Steel Bike Rim Correct Tool Bicycle Spoke Tool-Black

KWD 3.500

Oumers 3 Pack of Bike Spoke Wrench Kit, Forged Steel Bike Rim Correct Tool Bicycle Spoke Tool-Black

KWD 3.500

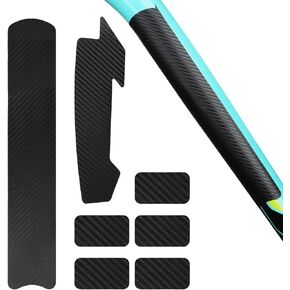

Oumers 7 Pieces Bicycle Frame Protection Stickers, Mountain Bike Frame Guard Tape Self-Adhesive Bicycle Protection Bike Anti Scratch Frame Decals Bike Chain Guards Stickers

KWD 3

Oumers 7 Pieces Bicycle Frame Protection Stickers, Mountain Bike Frame Guard Tape Self-Adhesive Bicycle Protection Bike Anti Scratch Frame Decals Bike Chain Guards Stickers

KWD 3

Oumers Bicycle 26-Piece Tire Repair Tools, Bike Tire Patch Repair Kit Tube Repair Kit with Vulcanizing Patches, Self-Adhesive Patchs, Schrader Valve Core, Metal Rasp, Lever, Storage Box(No Glue)

KWD 4

Oumers Bicycle 26-Piece Tire Repair Tools, Bike Tire Patch Repair Kit Tube Repair Kit with Vulcanizing Patches, Self-Adhesive Patchs, Schrader Valve Core, Metal Rasp, Lever, Storage Box(No Glue)

KWD 4

Bike Hub Conversion Adapter, 1 Pcs Alloy Front Rear Boost Hub Adapter Bike Boost Hub Conversion with Washers Screws for DIY Bikes

KWD 4

Bike Hub Conversion Adapter, 1 Pcs Alloy Front Rear Boost Hub Adapter Bike Boost Hub Conversion with Washers Screws for DIY Bikes

KWD 4