- Shopping, made easy.

- /

- Get the app!

Package: 1set hotend installed with ceramic heater and thermistor and hardened steel nozzle 0.4; 1pc extra 0.8mm plated copper nozzle; 2x cables, and some tools

Adjustable Metal CR10 Z-Axis T8 Lead Screw Top Mount Compatible with Tornado AM8 CR10 V3 CR10S Pro Ender 3 V2 Pro BLV Z-Rod Bearing Holder Aluminum Profiles Frame 3D Printer Upgrade

KWD 4.500

Adjustable Metal CR10 Z-Axis T8 Lead Screw Top Mount Compatible with Tornado AM8 CR10 V3 CR10S Pro Ender 3 V2 Pro BLV Z-Rod Bearing Holder Aluminum Profiles Frame 3D Printer Upgrade

KWD 4.500

2-Pack Upgrade 2-in-1 Ender 3 Oldham Coupling Z axis 8mm Lead Screw Nut for CR10 S4 S5 Ender 3 Pro V2 Neo Series Ender-3 S1 Pro CR10S PRO 3D Printer (2)

KWD 7

2-Pack Upgrade 2-in-1 Ender 3 Oldham Coupling Z axis 8mm Lead Screw Nut for CR10 S4 S5 Ender 3 Pro V2 Neo Series Ender-3 S1 Pro CR10S PRO 3D Printer (2)

KWD 7

Mini Hotend Kit with Upgraded Titanium TC4 Mini Heatbreak + Plated Wear Nozzle 0.4mm for Prusa Mini Mini+ 3D Printer Hot End

KWD 11

Mini Hotend Kit with Upgraded Titanium TC4 Mini Heatbreak + Plated Wear Nozzle 0.4mm for Prusa Mini Mini+ 3D Printer Hot End

KWD 11

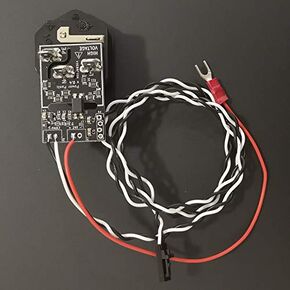

PSU Power Panic V 0.4 High Voltage with 10A 250V Fuse Switch and Cable,Power Supply Power Detection Module Socket for Prusa i3 Mk3 MK3S 3D Printer

KWD 6.500

PSU Power Panic V 0.4 High Voltage with 10A 250V Fuse Switch and Cable,Power Supply Power Detection Module Socket for Prusa i3 Mk3 MK3S 3D Printer

KWD 6.500