- Shopping, made easy.

- /

- Get the app!

Re-commended slicer setting:

retraction speed over 80MM/S

retraction length 2.5-4MM

If you are facing PLA clogging problem, please try the followings:

1. Increase the retraction speed. The speed may have being limited in the firmware try to change it. G-command "M203 E200"

2. Increase the extruder acceleration. Check your firmware settings. G-command "M201 E9000"

3. Reduce the retraction length. It depends on your machine setup.

4. Increase the nozzle temperature by 5-10 degrees.

5. Do not install the 2 screws for support the heatblcok like the stock hotend on the CR-10 printer.

6. Make sure that there is no gap between the heatsink and the heat breaker.

NOTE:

This product only supports 1.75mm filament!!! Not compatible CR10S PRO.

We found that many customers do not know how to properly install the nozzle.

Remember the core issues in the installation process.

Just make sure your nozzle and HEAT BREAK front end are tight and sealed. Otherwise, the filament will leak along the screw holes.

Packing list:

MK8 Brass Nozzle 1.75/0.4mm x 1

Titanium alloy heat break 1.75MM x 1

Aluminum Heater Block x 1

Aluminium Heatsink x 1

Silicone socks x 1

Motor Connection Cable,3D Printer Stepper Motor Cable Terminal Connector Cable,1.5M/4.92FT,Double Z Axis,Durable and Precise Design,Suitable for CR-10 CR-10S/Ender-3

KWD 3.500

Motor Connection Cable,3D Printer Stepper Motor Cable Terminal Connector Cable,1.5M/4.92FT,Double Z Axis,Durable and Precise Design,Suitable for CR-10 CR-10S/Ender-3

KWD 3.500

3D Printer Parts DRV8825 Stepper Motor Driver Module with Heat Sink for Ramps 1.4 StepStick A4988 (5pcs)

KWD 5.500

3D Printer Parts DRV8825 Stepper Motor Driver Module with Heat Sink for Ramps 1.4 StepStick A4988 (5pcs)

KWD 5.500

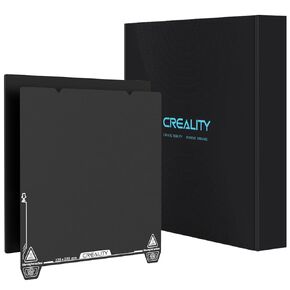

Creality Official Ender 3 V3 SE Original Build Plate Spring Steel Texture Surface Bed Plate Magnetic Flexible Removable Printing Bed for Ender 3 S1 Ender 3 S1 Pro Ender 3 Pro Ender 5 Pro

KWD 11.500

Creality Official Ender 3 V3 SE Original Build Plate Spring Steel Texture Surface Bed Plate Magnetic Flexible Removable Printing Bed for Ender 3 S1 Ender 3 S1 Pro Ender 3 Pro Ender 5 Pro

KWD 11.500

BIGTREETECH Direct BLTouch V3.1 Auto Bed Leveling Sensor+1.5m Extension Cable for Ender 3 Ender 5 Series 3D Printer with SKS Mini E3,Octopus

KWD 18.500

BIGTREETECH Direct BLTouch V3.1 Auto Bed Leveling Sensor+1.5m Extension Cable for Ender 3 Ender 5 Series 3D Printer with SKS Mini E3,Octopus

KWD 18.500