- Shopping, made easy.

- /

- Get the app!

Zeluga 878-156, 883-892, 878-179, 877-761, 885-638, 877-993 and 877-826 Bumper, PU Sheet, Gasket, Driver, Feeder O-Ring, Feeder Spring and Pushing Lever Spring Repair Kit for NV45AA, NV45AB, NV45AB2M Pneumatic Coil Roofing Nailer All these components are found in a repair or maintenance kit for a pneumatic coil roofing nailer. Bumper made from durable rubber and loacted inside the head of the nailer. It absorbs the shock and provide cushioning when piston cycles back after driving a nail. PU sheet is used for its resistance and durability to abrasion and impact. Gaskets are used to prevent air leaks and seal connections. These gasket are mostly found between two parts of nailer body or in the air flow system. The driver plays important role as it drives the nail into the roofing materials. Nailer part that makes direct contact with the nail head. The feeder O-Ring are the essential for maintaining the correct pressure and function in the feeding system. It helps in smooth operation and prevent air leaks. The feeder spring are the parts that applies pressure to the stack of nails, that they are pushed forward into position to be fired. The pushing lever spring is the part of mechanism that advances the nails into position. Ensure consistent nails feeding as it works in conjuction with the feeder spring.

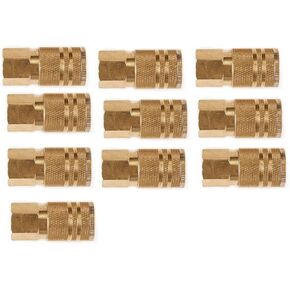

22-154 10 Pc. 1/4in. NPT 6 Ball Industrial Brass Female Coupler

KWD 8.500

22-154 10 Pc. 1/4in. NPT 6 Ball Industrial Brass Female Coupler

KWD 8.500

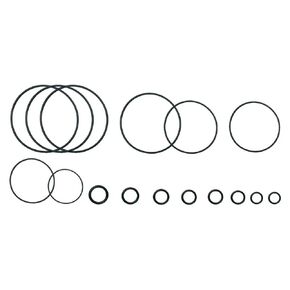

31-404 G845 O-Ring Kit for NV45AA, NV45AB, NV45AB2M Pneumatic Coil Roofing Nailer (16 Pack)

KWD 6.500

31-404 G845 O-Ring Kit for NV45AA, NV45AB, NV45AB2M Pneumatic Coil Roofing Nailer (16 Pack)

KWD 6.500

-11%

31-399 878-179 Piston Bumper for Hitachi NV45AA, NV45AB, NV45AB2M Pneumatic Coil Roofing Nailer, Framing Nailer Part

KWD 4

-11%

31-399 878-179 Piston Bumper for Hitachi NV45AA, NV45AB, NV45AB2M Pneumatic Coil Roofing Nailer, Framing Nailer Part

KWD 4

22-172 1/4in. ID x 1/4in. MPT Reusable Strain Relief Replacement Fitting Rigid

KWD 3.500

22-172 1/4in. ID x 1/4in. MPT Reusable Strain Relief Replacement Fitting Rigid

KWD 3.500